So you are looking for a new cnc router table? Well there are many different options out there. Below are our options and tips for finding and using the best cnc router table for your project needs.

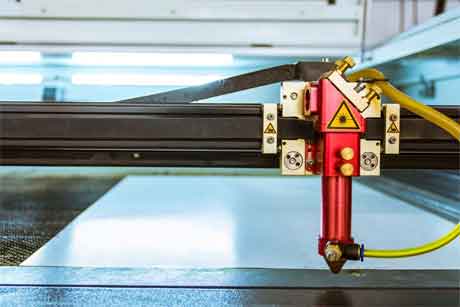

First up, what is a cnc router table top?

The cnc router table top, also called the cutting bed, is where all the cutting happens. There are a few different options out there depending on what kind of material you will be cutting, engraving or routing.

What is the best design for a cnc table router?

Often, the importance of the design of the cnc router table is overlooked. This can be where you can gain an advantage here. Getting the right table will enable you to be a lot more productive and allow you to work with your specific materials a lot faster.

T-Slot cnc router table

If you are working with many different types of material and shapes, then I would suggest going with a T-slot style bed. The T-slots will enable you to clamp your material onto the bed in a number of different ways. You can get specialized T-slot clamps that will fit in nicely to the table top cnc router.

Perforated table top

Another option is the perforated table top. This is another common one for the cnc table top router and is cheaper than a T-slot cnc table top router. Because of the slots or holes cut into a table top like this, it makes the table top a lot lighter and more affordable.

Vacuum table top for a cnc router table

Other advances include the vacuum table. This uses a vacuum to secure the material onto the table without the need for lamps. This is usually found on higher end, industrial type machines. Some of the more advanced vacuum systems allow you to section off different parts of the table to make setting up parts faster and easier, you can find out more.

Some of the advantages include a full support for thin or weaker materials as well as it being easy to use, as no clamping is needed.

Disadvantages could include the fact that you need a good supply of air flow to be effective and large volume vacuum blowers can be costly and noisy.

Vacuum tables are more suited for cutting nested sheets, as this takes full advantage of the whole table.

Disposable table – mdf/particle board

A disposable table is usually particle or mdf board. This is cheap to acquire and can be cut to size when buying it at most hardware or supply stores.

This cheap material is used as more for a temporary or disposable table and is usually sandwiched between the material and a T-slot or perforated table top, so that the actual table top does not get ruined.

A good idea is to screw or glue a piece of material onto a piece of mdf or particle board and clamp the board instead. This increases the area in which you can clamp and secure the material to the machine bed.

DIY cnc router table

There are a ton of different people out there who go the diy route. In this case, there are many different kinds of styles, some even a hybrid of some of the above methods. It all really depends on the project you will be doing and what you intend to do with the cnc machine.

There are many free resources, including the biggest cnc forum, cnczone and other videos online to get you going. There are also many free software packages and operating system packages that you can get for cad and cam purposes online.

Some free favorites include Ubuntu for the operating system and Inkscape for a free open source program for vector-based work.

Used cnc router table

If you can not find a good cnc router table for sale, then it may be worth your time to find a used one. A used cnc router table can often be bought for cheap, but are hard to find. If you want something cheap, I suggest using mdf/ particle board to make a temporary table top, or as a protective layer over an existing cnc engraving machine table top.